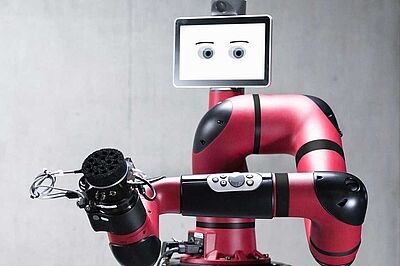

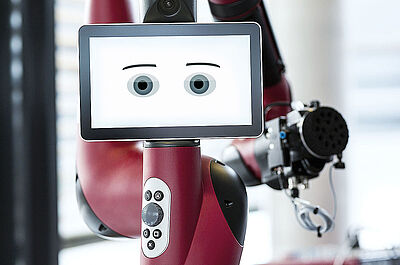

Sawyer BLACK Edition

In the BLACK Edition, Sawyer remains the easy to use, flexible and highly accepted collaborative robot.

One year after the takeover of the assets by the HAHN Group, Rethink Robotics presents the Sawyer BLACK Edition. The improved hardware is based on the combination of German engineering competence and many years of application experience. Cobot Sawyer is now quieter and more durable with a higher product quality.

The use of the Sawyer BLACK Edition contributes to a quieter work environment and makes the Cobot with the friendly face even more popular among employees. Thanks to its robot arm with 7 degrees of freedom and a range of 1,260 mm, Sawyer can also be used where there is no space for human employees. Possible areas of application include tasks that are dangerous or monotonous for humans, such as CNC machine assembly, circuit board assembly, metal processing, injection molding, packaging, loading and unloading, as well as tests and inspections. The Cobot solution is ready for use immediately after delivery and equipped with the powerful Intera software and two camera systems. Learn more.

The human workforce quickly accepts Sawyer, thanks to his friendly design. Sawyer is delivered as an out-of-the-box Cobot solution, equipped with the powerful Intera software and two integrated camera systems. The built-in force-sensing capabilities allow Sawyer, also as BLACK Edition, to make adaptive decisions while executing tasks. This way he can perform his tasks quickly and accurately, but without becoming a danger to his human colleagues.

Rethink Robotics with its collaborative robot Sawyer stands for:

Software Driven Hardware: Easy application

A collaborative robot manufacturer that provides a cobot solution with a powerful, easy to use software – the Intera software - that is continually updated and delivers production metrics in real-time. The combination of hardware and software, together with the ClickSmart gripper technology, allows Sawyer to be deployed faster and easier in more tasks and applications, and without time-consuming customization. The robot can be trained by simply demonstrating the procedure moving its arm. The robot is up and running to perform a task within a matter of minutes and easy to use. That’s the Rethink difference – Intera makes Sawyer fast and easy to deploy.

Embedded and External Vision: Flexibility

Sawyer comes with an embedded Cognex Vision System in its arm that enables the Robot Positioning System (RPS) to provide for a dynamic reorientation and easy redeployment of the robot. With it´s 7 degrees of freedom and a 1260 mm reach, Sawyer fits into a variety of work cells – even ones already designed for people. It can maneuver into tight spaces, and around fixtures and doors, much like a human arm. The combination with the easy to use software enables a wide variety of applications without requiring additional hardware, software, or integration. That’s the Rethink difference – Intera makes Sawyer flexible to use.

High Resolution Force Control: Highly accepted by employees

While traditional industrial robots have to be kept behind cages, Sawyer is inherently safe, designed to work alongside people, and certified that it meets ISO requirements by TÜV Rheinland (ISO 10218-1:2011 and PLd Cat. 3). The safetyness in combination with his friendly eyes makes Sawyer not only higly accepted but also popular among employees.

Thanks to sensitive torque sensors embedded into every joint, Sawyer’s built in force-sensing allows constant force control where delicate part insertion is critical, or to use force feedback in tasks where verification of properly seated parts is needed. By controlling both force and position, Saywer controls the amount of force it applies to different directions, the same way people do when performing tasks, eliminating the need for additional sensors or hardware.